China-developed Domestic Chip Solutions

Through-type taillights are becoming a trend, appearing in cars from domestic, luxury, and supercar brands.

A recent post about through-type taillight solutions has gone viral. With the rise of China-developed automotive-grade chips. We specializing in this field for six years, can fully support the chips involved in this solution. Stay tuned!

1. Overview

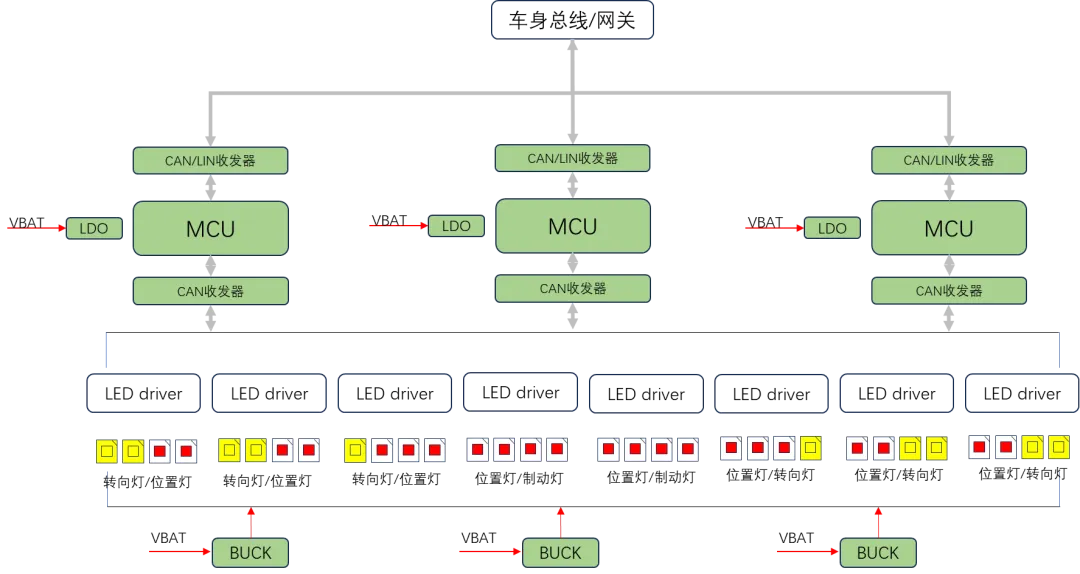

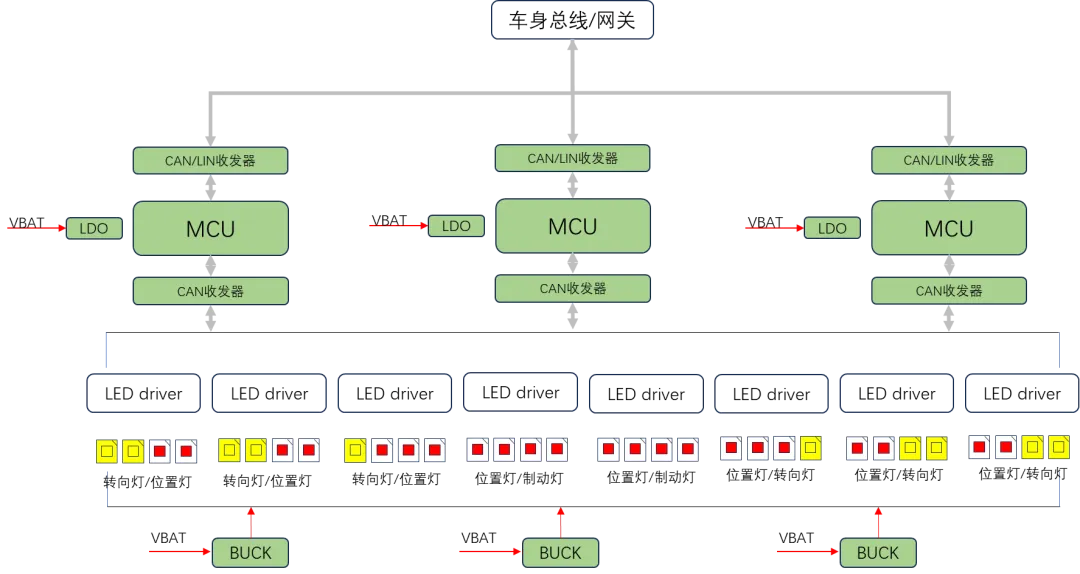

2.The common through-type taillight solution:

2.The common through-type taillight solution:

Each fixed side uses an MCU to control the turn signal, position, and brake lights, often combining position and brake lights to reduce costs with LED drivers.

The movable side uses one MCU for the turn signal, through-type position, and brake lights.

The three MCUs synchronize via CAN or LIN bus for lighting effects and communication with other ECUs.

3.As shown in the block diagram, the through-type taillight solution primarily includes the following chips:

Main control chip: MCU with M0+/M3/M4 cores, chosen based on software complexity.

Power chip: BUCK DC-DC and 40V-rated LDO

Driver chip: 12/16/24-channel linear constant current chip

Communication chip: CAN, CAN-FD, LIN transceivers

3.1. Main Control Chip: Recommended MCU from Autochips

The taillight’s main control chip has low resource demands. An AC7801/AC7811 series MCU with M0/M3 cores is sufficient, requiring peripherals like one CAN, one LIN, one UART, one ADC, and around 128K Flash.

For information or functional safety, the MCU needs encryption, safety certification, and AutoSAR support, increasing the Flash requirement. The AC7840x series with M4 cores can provide 512K to 1MB or more Flash, depending on AutoSAR software needs.

3.2. Power Chip: Recommended LDO, DC-DC, and LED Drivers from LEN

The power chips used in the taillight solution are of two types:

Buck DC-DC, converting the vehicle battery's 12V to around 8V to power the LED lights and drivers.

LDO, converting the 12V to around 5V to power the MCU and CAN transceiver.

LEN’s LDO series (100mA to 500mA) has extensive production experience and has been successfully implemented in mass production for automotive applications.

3.3. Communication Chip: Recommended CAN/LIN Transceivers from SIT

The communication chips used are CAN and LIN transceivers.

LIN is for MCU-to-MCU or MCU-to-ECU communication.

CAN is used for MCU-to-ECU communication and MCU-to-LED driver via UART to CAN.